VANCOUVER, British Columbia –

Capstone Mining Corp. (“Capstone” or the “Company”) (TSX:CS) announces that its Pinto Valley mine has successfully demonstrated positive economics from enhanced dump leach performance by partnering with Jetti Resources, LLC (“Jetti”) to apply their novel patented catalytic technology at Pinto Valley’s existing dump leach operation.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20200727005208/en/

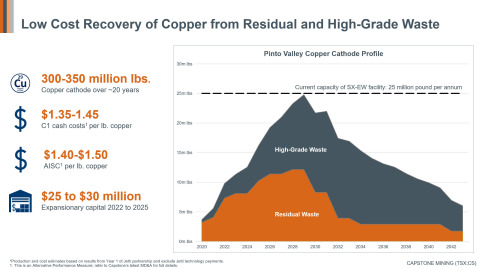

Figure 1: Low Cost Recovery of Copper from Residual and High-Grade Waste. The plan is to increase cathode production to 300-350 million pounds from residual and high-grade waste over the next two decades, creating 30 new jobs at Pinto Valley. (Graphic: Business Wire)

HIGHLIGHTS

During the first year of Capstone’s partnership with Jetti, cathode production per area irrigated has doubled (see Figure 3). A plan to increase activity is being implemented with the goal of generating strong cash flow from Pinto Valley’s underutilized 25 million pound per year solvent extraction and electrowinning (“SX-EW”) plant, which is currently operating at only 20% of capacity. The plan is to increase cathode production to 300-350 million pounds from residual and high-grade waste over the next two decades (see Figure 1), creating 30 new jobs at Pinto Valley.

Figure 1: Low Cost Recovery of Copper from Residual and High-Grade Waste

Darren Pylot, Capstone’s President and CEO said, “The mining industry has long been pursuing a viable technology to leach low-grade chalcopyrite ores. The results after year one of our partnership with Jetti Resources are exciting because it means we can generate high margin from material that would have been waste. This project represents an opportunity to position Pinto Valley more competitively, which will create and sustain jobs, and economic benefits in a socially and environmentally responsible manner.”

The engagement of Jetti and utilization of their proprietary technology was an extension of Pinto Valley’s existing PV3 Optimization Study, which is focused on several low capex, high impact projects aimed at having a material increase to the net present value of the operation. The PV3 Optimization Study is scheduled for release in Q4 2020.

JETTI NOVEL CATALYST TECHNOLOGY

Jetti’s patented technology makes it possible to extract copper from low-grade primary sulfides, such as chalcopyrite, the world’s most abundant copper mineral ore. Jetti has developed and commercially deployed a catalytic technology that allows for the efficient and effective heap and stockpile leach extraction of copper trapped in these challenging mineral ores. Jetti’s catalysts enable the disruption of the sulfur metal bond of the mineral, allowing copper extraction to take place unimpeded. As a result, Jetti is now increasing profitability at operations and extending project life, while also converting uneconomic waste rock into valuable assets.

Figure 2: Surface of Chalcopyrite Leach Residue With and Without Jetti Catalyst

Mike Outwin, Jetti Resources Co-Founder and CEO said, “Pinto Valley was a perfect candidate to pioneer our breakthrough technology given the abundance of copper resources available for leaching and the underutilized plant and infrastructure in place. Our technology has integrated seamlessly with the existing infrastructure on site, and we have doubled the production of copper cathode per area irrigated within one year of our partnership. We are excited to partner with Capstone to realize more economic value from their vast copper resource in Arizona and possibly other projects in the Americas.”

Figure 3: Copper Cathode Production Per Area Irrigated Doubled

In 2019, Jetti started deploying its novel catalytic technology at Pinto Valley’s leach operation and, one year later, has now doubled copper cathode production per area irrigated.

PINTO VALLEY’S CATHODE PRODUCTION HISTORY

Pinto Valley started producing copper cathode in 1981 from material below the cut-off grade of its mill that had been stockpiled since the early 1970s (see Figure 4). This provided a 12 to 15% boost to total copper production as cathode accounted for an average of 16 million pounds per annum through to the early 2000s. Since then, the production of copper cathode has decreased consistently to under four million pounds per annum due to the impact of reduced leach kinetics as chalcopyrite is subjected to a passivation layer inhibiting further breakdown.

Figure 4: Historical Production at Pinto Valley

NEXT STEPS

As a result of the positive commercial demonstration phase, Pinto Valley intends to significantly expand leaching activity, targeting approximately 280 to 300 million tonnes of historic leach stockpile and 175 to 185 million tonnes of high-grade waste already scheduled for removal over the remaining 19 years of mine life. Potential to increase the mill cut-off grade to bolster copper concentrate production, thereby increasing the tonnage of high-grade waste available for leaching, will be studied during H2 2020. An updated NI 43-101 Technical Report is expected in 2021.

Figure 5: Pinto Valley Dump Leach Area

Figure 6: Aerial Photo of 25 Million Pound Per Year SX-EW Plant

The SX-EW plant is currently only 20% utilized.

Figure 7: High-Grade Waste Area

A total of 11 to 12 million tonnes of high-grade waste has been placed since early 2019 and by the end of 2022, approximately 48 to 52 million tonnes are expected to be under irrigation.

Figure 8: July 2020 – LME Grade A Copper Cathode Waiting for Pick-Up

ABOUT CAPSTONE MINING CORP.

Capstone Mining Corp. is a Canadian base metals mining company, focused on copper. Our two producing mines are the Pinto Valley copper mine located in Arizona, US and the Cozamin copper-silver mine in Zacatecas State, Mexico. In addition, Capstone has a large scale, fully-permitted, 70% owned copper-iron-gold Santo Domingo project in Region III, Chile, in partnership with Korea Resources Corporation, as well as a portfolio of exploration properties. Capstone’s strategy is to focus on the optimization of operations and assets in politically stable, mining-friendly regions, centred in the Americas. We are committed to the responsible development of our assets and the environments in which we operate. Our headquarters are in Vancouver, Canada and we are listed on the Toronto Stock Exchange (TSX). Further information is available at www.capstonemining.com.

COMPLIANCE WITH NI 43-101

Unless otherwise indicated, Capstone has prepared the technical information in this news release based on information contained in the technical reports and news releases (collectively the “Disclosure Documents”) available under Capstone Mining Corp.’s company profile on SEDAR at www.sedar.com. Each Disclosure Document was prepared by or under the supervision of a qualified person (a “Qualified Person” or “QP”) as defined in National Instrument 43-101 – Standards of Disclosure for Mineral Projects of the Canadian Securities Administrators (“NI 43-101”). For readers to fully understand the information in this news release, they should read the Technical Reports (available on www.sedar.com) in their entirety, including all qualifications, assumptions and exclusions that relate to the information set out in this presentation which qualifies the Technical Information. Readers are advised that mineral resources that are not mineral reserves do not have demonstrated economic viability. The Disclosure Documents are each intended to be read as a whole, and sections should not be read or relied upon out of context. The Technical Information is subject to the assumptions and qualifications contained in the Disclosure Documents. For further details refer to the Company’s NI 43-101 Technical Reports for Pinto Valley Mine Life Extension – Phase 3 (PV3) Pre-feasibility Study, Miami, Arizona, published Feb 23, 2016, effective Jan 1, 2016.

The Technical Information in this presentation has been prepared in accordance with NI 43-101 and reviewed and approved by Colleen Roche, Capstone Pinto Valley’s Manager, Operations Support, a Qualified Person as defined in NI 43-101.

CAUTIONARY NOTE REGARDING FORWARD-LOOKING INFORMATION

This news release, and the documents incorporated by reference herein, contains “forward-looking information” within the meaning of Canadian securities legislation and “forward-looking statements” within the meaning of the United States Private Securities Litigation Reform Act of 1995 (collectively, “forward-looking statements”). These forward-looking statements are made as of the date of this document and Capstone Mining Corp. (“Capstone” or the “Company”) does not intend, and does not assume any obligation, to update these forward-looking statements, except as required under applicable securities legislation. Forward-looking statements relate to future events or future performance and reflect our expectations or beliefs regarding future events. Forward-looking statements include, but are not limited to, statements with respect to the continuing success of mineral exploration, Capstone’s ability to fund future exploration activities, the estimation of mineral resources and mineral reserves, the realization of mineral reserve estimates, the timing and amount of estimated future production, costs of production and capital expenditures, the success of our mining operations, the estimation of increased cathode production, the ability to obtain required permits for the intended expanded leaching activity, the estimation of the expected economics of the expanded leaching activities, the estimations for potential quantities and grade of inferred resources and exploration targets, environmental risks, unanticipated reclamation expenses and title disputes. In certain cases, forward-looking statements can be identified by the use of words such as “plans”, “expects”, “aiming”, “approximately”, “guidance”, “scheduled”, “target”, “estimates”, “forecasts”, “extends”, “convert”, “potential”, “intends”, “anticipates”, “believes” or variations of such words and phrases, or statements that certain actions, events or results “may”, “could”, “should”, “would”, “will”, “might” or “will be taken”, “occur” or “be achieved” or the negative of these terms or comparable terminology. By their very nature, forward-looking statements involve known and unknown risks, uncertainties and other factors that may cause our actual results, performance or achievements to be materially different from any future results, performance or achievements expressed or implied by the forward-looking statements. Such factors include, amongst others, risks related to inherent hazards associated with mining operations and closure of mining projects, the inherent uncertainty of mineral exploration and estimations of exploration targets, potential delays in exploration or interruption of production directly or indirectly related to COVID-19 or governmental action, future prices of copper and other metals, compliance with financial covenants, surety bonding requirements, our ability to raise capital or fund explorations, Capstone’s ability to acquire properties for growth, counterparty risks associated with sales of our metals, foreign currency exchange rate fluctuations, changes in general economic conditions, risks associated with hedging strategies, accuracy of mineral resource and mineral reserve estimates, operating in foreign jurisdictions with risk of changes to governmental regulation, compliance with governmental regulations, compliance with environmental laws and regulations, reliance on approvals, licences and permits from governmental authorities, impact of climatic conditions on our operations, aboriginal title claims and rights to consultation and accommodation, land reclamation and mine closure obligations, uncertainties and risks related to the potential development of the Cozamin project, increased operating and capital costs, challenges to title to our mineral properties, maintaining ongoing social license to operate, dependence on key management personnel, potential conflicts of interest involving our directors and officers, corruption and bribery, limitations inherent in our insurance coverage, labour relations, increasing energy prices, competition in the mining industry, risks associated with joint venture partners, our ability to integrate new acquisitions into our operations, cybersecurity threats, legal proceedings, and other risks of the mining industry as well as those factors detailed from time to time in the Company’s interim and annual financial statements and MD&A of those statements, all of which are filed and available for review under the Company’s profile on SEDAR at www.sedar.com. Although the Company has attempted to identify important factors that could cause our actual results, performance or achievements to differ materially from those described in our forward-looking statements, there may be other factors that cause our results, performance or achievements not to be as anticipated, estimated or intended. There can be no assurance that our forward-looking statements will prove to be accurate, as our actual results, performance or achievements could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on our forward-looking statements.

View source version on businesswire.com: https://www.businesswire.com/news/home/20200727005208/en/

Jerrold Annett, VP, Strategy and Capital Markets

416-572-2272

Virginia Morgan, Manager, IR and Communications

604-674-2268